10 Best Welding Wire 2025 in the United States

Winner

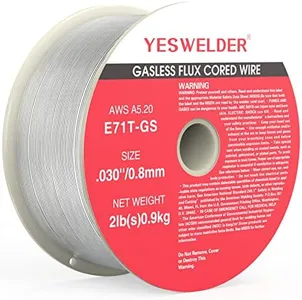

YESWELDER Flux Core Gasless Mig Wire, Mild Steel E71TGS .030-Diameter, 2-Pound Strong ABS Plastic Spool

The YESWELDER Flux Core Gasless Mig Wire is designed for mild steel welding, with a diameter of .030 inches and a 2-pound spool size. As a flux-cored wire, it does not require shielding gas, making it suitable for outdoor welding, especially in windy conditions. This is a great advantage as it provides flexibility and simplicity in various environments.

Most important from

6935 reviews

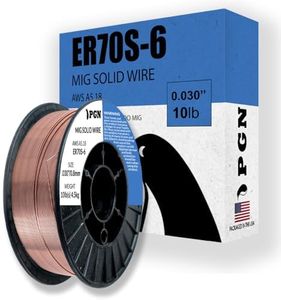

PGN Solid MIG Welding Wire - ER70S-6 .030 Inch - 10 Pound Spool - Mild Steel MIG Wire with Low Splatter and High Levels of Deoxidizers - For All Position Gas Welding

The PGN Solid MIG Welding Wire - ER70S-6 is a solid choice for anyone involved in welding, whether you're a professional, a metalworking hobbyist, or a DIY enthusiast. Its mild steel composition and 0.030-inch diameter cater to a variety of welding projects, making it versatile for different applications like T-joints, butt welds, and lap welds. A key highlight is its low splatter feature, which significantly enhances the quality of your welds by delivering cleaner results, thus portraying a more professional appearance.

Most important from

1922 reviews

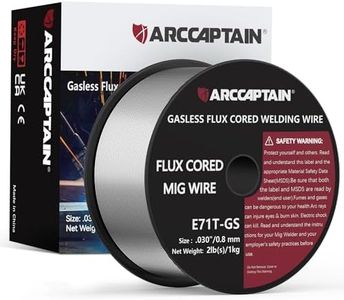

ARCCAPTAIN Flux Core Welding Wire .030, E71T-GS Mig Welding Wire 2-Pound Spool Gasless Mild Carbon Steel Compatible With Lincoln Miller Forney Harbor Welder

The ARCCAPTAIN Flux Core Welding Wire .030 offers a convenient welding solution, especially for those who prefer gasless welding. Its 0.030-inch diameter is suitable for a variety of welding tasks including T-joints, butt welds, and lap welds, making it versatile for different projects. A significant advantage is that it does not require shielding gas, which simplifies the setup process and is perfect for outdoor or less controlled environments where gas might be impractical.

Most important from

1880 reviews

Top 10 Best Welding Wire 2025 in the United States

Winner

9.9 score

YESWELDER Flux Core Gasless Mig Wire, Mild Steel E71TGS .030-Diameter, 2-Pound Strong ABS Plastic Spool

YESWELDER Flux Core Gasless Mig Wire, Mild Steel E71TGS .030-Diameter, 2-Pound Strong ABS Plastic Spool

Chosen by 1284 this week

PGN Solid MIG Welding Wire - ER70S-6 .030 Inch - 10 Pound Spool - Mild Steel MIG Wire with Low Splatter and High Levels of Deoxidizers - For All Position Gas Welding

PGN Solid MIG Welding Wire - ER70S-6 .030 Inch - 10 Pound Spool - Mild Steel MIG Wire with Low Splatter and High Levels of Deoxidizers - For All Position Gas Welding

ARCCAPTAIN Flux Core Welding Wire .030, E71T-GS Mig Welding Wire 2-Pound Spool Gasless Mild Carbon Steel Compatible With Lincoln Miller Forney Harbor Welder

ARCCAPTAIN Flux Core Welding Wire .030, E71T-GS Mig Welding Wire 2-Pound Spool Gasless Mild Carbon Steel Compatible With Lincoln Miller Forney Harbor Welder

ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6 10Lbs Gas Solid Carbon Steel Low Splatter Mig Welding Wire Compatible With Lincoln Miller Forney Harbor Welder 0.08 4.5KG

ARCCAPTAIN Mig Welding Wire, 0.030 10Lb Mig Wire ER70S-6 10Lbs Gas Solid Carbon Steel Low Splatter Mig Welding Wire Compatible With Lincoln Miller Forney Harbor Welder 0.08 4.5KG

Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon Steel Welding Wire, All Position, Low Spatter, Formulated to Provide Porosity-Free, X-Ray Quality Welds, 0.03 dia

Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon Steel Welding Wire, All Position, Low Spatter, Formulated to Provide Porosity-Free, X-Ray Quality Welds, 0.03 dia

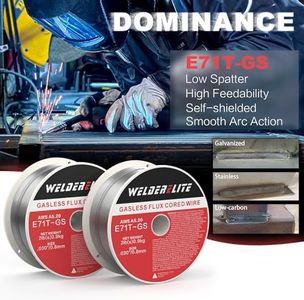

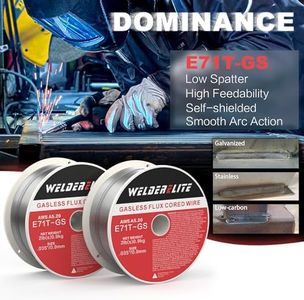

WelderElite 2-Pack 0.030" Gasless Flux Core Wire, 2lb Each, Perfect for MIG Welding Galvanized, Stainless & Mild Steel Projects, E71T-GS

WelderElite 2-Pack 0.030" Gasless Flux Core Wire, 2lb Each, Perfect for MIG Welding Galvanized, Stainless & Mild Steel Projects, E71T-GS

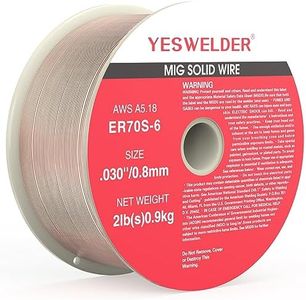

YESWELDER ER70S-6 .030-Inch on 2-Pound Spool Carbon Steel Mig Solid Welding Wire

YESWELDER ER70S-6 .030-Inch on 2-Pound Spool Carbon Steel Mig Solid Welding Wire

Hobart H305408R22 ER70S-6 10-Pound ER70S-6 Carbon-Steel Solid Welding Wire, 0.035-Inch

Hobart H305408R22 ER70S-6 10-Pound ER70S-6 Carbon-Steel Solid Welding Wire, 0.035-Inch

7.9 score

Lincoln Electric ED030584, MIG Welding Wire, NR-211-MP.035, Spool - 2 Pack

Lincoln Electric ED030584, MIG Welding Wire, NR-211-MP.035, Spool - 2 Pack

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.