10 Best Welding Helmets 2025 in the United States

Winner

YESWELDER Large Viewing Screen 3.93"X3.66" True Color Solar Power Auto Darkening Welding Helmet, 4 Arc Sensor Wide Shade 4/5-9/9-13 for TIG MIG Arc Weld Grinding Welder Mask LYG-M800H

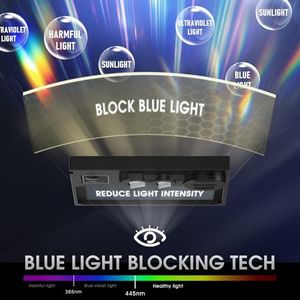

The YESWELDER Large Viewing Screen Welding Helmet is designed for various welding applications such as TIG, MIG, and MMA, as well as plasma cutting and grinding. One of its standout features is the super large viewing area of 3.93" x 3.66", which, combined with four premium sensors, ensures excellent visibility and helps you stay aware of your surroundings while working. The True Color technology enhances clarity and provides a more realistic color view, which can reduce eye strain over long periods of use.

Most important from

11097 reviews

YESWELDER True Color Solar Powered Auto Darkening Welding Helmet, Wide Shade 4/9-13 for TIG MIG ARC Grind Welding Hood Helmet

The YESWELDER True Color Solar Powered Auto Darkening Welding Helmet is designed for various types of welding such as TIG, MIG, MMA, and grinding. It features an Auto-Darkening Filter (ADF) with a wide shade range of 4/9-13, which allows it to adapt quickly from light to dark in 1/30000 seconds, ensuring your eyes are protected from sudden flashes.

Most important from

17754 reviews

Lincoln Electric K3034-4 VIKING 3350 Auto Darkening Welding Helmet with 4C Lens Technology, Matte Black, extra large

The Lincoln Electric K3034-4 VIKING 3350 welding helmet stands out in the welding helmet category, particularly for its high-quality optical performance and user comfort. One of its most significant advantages is the 4C Lens technology, which offers exceptional clarity (rated 1/1/1/1), ensuring that welders can see their work with minimal distortion and color saturation. This clarity is crucial for precision in welding tasks. The helmet also boasts an extra-large viewing area of 12.5 square inches, which enhances visibility and allows for better control while working, making it a suitable choice for those who need to see a larger workspace clearly.

Most important from

1715 reviews

Top 10 Best Welding Helmets 2025 in the United States

Winner

9.8 score

YESWELDER Large Viewing Screen 3.93"X3.66" True Color Solar Power Auto Darkening Welding Helmet, 4 Arc Sensor Wide Shade 4/5-9/9-13 for TIG MIG Arc Weld Grinding Welder Mask LYG-M800H

YESWELDER Large Viewing Screen 3.93"X3.66" True Color Solar Power Auto Darkening Welding Helmet, 4 Arc Sensor Wide Shade 4/5-9/9-13 for TIG MIG Arc Weld Grinding Welder Mask LYG-M800H

Chosen by 1327 this week

YESWELDER True Color Solar Powered Auto Darkening Welding Helmet, Wide Shade 4/9-13 for TIG MIG ARC Grind Welding Hood Helmet

YESWELDER True Color Solar Powered Auto Darkening Welding Helmet, Wide Shade 4/9-13 for TIG MIG ARC Grind Welding Hood Helmet

Lincoln Electric K3034-4 VIKING 3350 Auto Darkening Welding Helmet with 4C Lens Technology, Matte Black, extra large

Lincoln Electric K3034-4 VIKING 3350 Auto Darkening Welding Helmet with 4C Lens Technology, Matte Black, extra large

ANDELI Welding Helmet - Panoramic 180° View 3.94"X3.74", LED Lighting True Color Auto Darkening Welding Helmet with Light, 4 Arc Sensor, 4/5-8/9-13 Type-C Charging

ANDELI Welding Helmet - Panoramic 180° View 3.94"X3.74", LED Lighting True Color Auto Darkening Welding Helmet with Light, 4 Arc Sensor, 4/5-8/9-13 Type-C Charging

ESAB® Sentinel™ A60 Welding Helmet, Black Low-Profile Design, High Impact Resistance Nylon, Large Viewing Area 4.65 in x 2.80 in

ESAB® Sentinel™ A60 Welding Helmet, Black Low-Profile Design, High Impact Resistance Nylon, Large Viewing Area 4.65 in x 2.80 in

Lincoln Electric Viking 2450 ADV Series Black Welding Helmet - Integrated LED - K3028-5

Lincoln Electric Viking 2450 ADV Series Black Welding Helmet - Integrated LED - K3028-5

Miller 287803 Classic Series VS Welding Helmet, Auto-Darkening Welding Helmet, Black

Miller 287803 Classic Series VS Welding Helmet, Auto-Darkening Welding Helmet, Black

3M Speedglas Heavy-Duty Welding Helmet G5-01 with G5-01VC ADF and Adflo High-Altitude PAPR Assembly, Bluetooth, Natural Color Technology, 46-1101-30iVC

3M Speedglas Heavy-Duty Welding Helmet G5-01 with G5-01VC ADF and Adflo High-Altitude PAPR Assembly, Bluetooth, Natural Color Technology, 46-1101-30iVC

7.4 score

Jackson Safety Premium Graphic Welding Hood with ADF - Ultra Lightweight Auto Darkening Welding Helmet - ANSI Z87.1 (Multiple Styles)

Jackson Safety Premium Graphic Welding Hood with ADF - Ultra Lightweight Auto Darkening Welding Helmet - ANSI Z87.1 (Multiple Styles)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.