10 Best Sticker Cutting Machines 2025 in the United States

Winner

Cricut Explore 3 Smart Cutting Machine - Vinyl Starter Bundle

The Cricut Explore 3 Smart Cutting Machine is a versatile tool for DIY enthusiasts, offering a wide range of capabilities. It works with over 100 materials including vinyl, iron-on HTV, and cardstock. The bundle includes essential accessories such as a permanent vinyl roll, transfer tape, standard grip mats, and a 5-piece tool kit, making it a comprehensive package for beginners. The cutting width is substantial, allowing for a variety of project sizes. Additionally, its cutting force is suitable for most common crafting materials, ensuring precise and effective cuts.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Cricut Joy Xtra Smart Cutting Machine, White

The Cricut Joy Xtra Smart Cutting Machine in white is a versatile tool for crafting enthusiasts. It works with over 50 different materials, including popular choices like vinyl, iron-on, and cardstock. This makes it a great option for those looking to create a variety of projects. The machine is also compatible with home inkjet printers, allowing you to print and then cut full-color designs, which adds to its versatility.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Cricut Joy Machine & Digital Content Library Bundle - Includes 30 images in Design Space App - Portable DIY Smart Machine for creating customized cards, crafts, & labels

The Cricut Joy Machine & Digital Content Library Bundle is a portable and compact sticker-cutting machine, perfect for crafters looking to create customized cards, crafts, and labels. Weighing just 3.9 lbs, it's highly portable, making it easy for users to craft on-the-go. The machine includes a digital library of 30 images, which are automatically added to your account upon setup, enhancing the creative possibilities right from the start. Its cutting capabilities are impressive, as it can handle over 50 different materials, including popular options like cardstock, vinyl decal, and iron-on.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 10 Best Sticker Cutting Machines 2025 in the United States

Winner

10.0 score

Cricut Explore 3 Smart Cutting Machine - Vinyl Starter Bundle

Cricut Explore 3 Smart Cutting Machine - Vinyl Starter Bundle

Chosen by 1105 this week

Cricut Joy Xtra Smart Cutting Machine, White

Cricut Joy Xtra Smart Cutting Machine, White

Cricut Joy Machine & Digital Content Library Bundle - Includes 30 images in Design Space App - Portable DIY Smart Machine for creating customized cards, crafts, & labels

Cricut Joy Machine & Digital Content Library Bundle - Includes 30 images in Design Space App - Portable DIY Smart Machine for creating customized cards, crafts, & labels

Brother ScanNCut SDX125E Electronic DIY Cutting Machine with Scanner, Make Custom Stickers, Vinyl Wall Art, Greeting Cards and More with 682 Included Patterns,Titanium/Aqua

Brother ScanNCut SDX125E Electronic DIY Cutting Machine with Scanner, Make Custom Stickers, Vinyl Wall Art, Greeting Cards and More with 682 Included Patterns,Titanium/Aqua

Sizzix 660200 Big Shot Manual Die, 6 Inches

Sizzix 660200 Big Shot Manual Die, 6 Inches

Brother ScanNCut SDX85C Electronic DIY Cutting Machine with Scanner, Make Vinyl Wall Art, Appliques, Homemade Cards and More with 251 Included Patterns,Charcoal

Brother ScanNCut SDX85C Electronic DIY Cutting Machine with Scanner, Make Vinyl Wall Art, Appliques, Homemade Cards and More with 251 Included Patterns,Charcoal

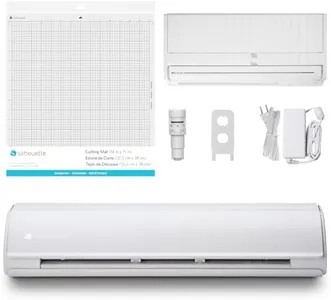

Silhouette Cameo 5 Plus 15 inch Vinyl Cutting Machine with Studio Software, Electric Tool and ES Mat Compatible, SNA and IPT, 50 db

Silhouette Cameo 5 Plus 15 inch Vinyl Cutting Machine with Studio Software, Electric Tool and ES Mat Compatible, SNA and IPT, 50 db

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.