10 Best Sanding Belts 2025 in the United States

Winner

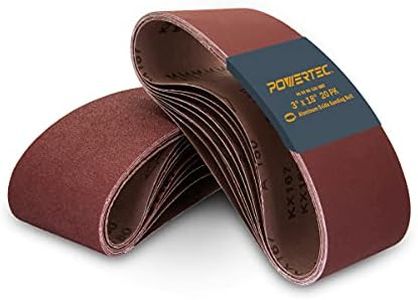

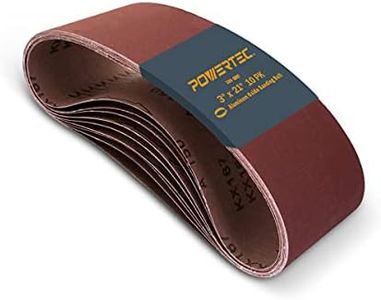

POWERTEC 4 x 24 Inch Sanding Belts, 30PK, 10 Each of 60 80 120 Grits, Aluminum Oxide Belt Sander Sanding Belt Assortment, Sandpaper for Oscillating Belt and Spindle Sander (110091)

The POWERTEC 4 x 24 Inch Sanding Belts are a versatile option for a variety of sanding tasks. This 30-pack includes 10 belts each of 60, 80, and 120 grits, making it suitable for different levels of sanding from coarse to fine. The belts are made of aluminum oxide, a durable material known for its resilience and effectiveness in sanding wood, aluminum, fiberglass, rubber, plastic, and non-ferrous metals. The backing is X-weight clothed, providing sturdy support, while the resin bond ensures the belts withstand heavy-duty use without breaking easily.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!3M Cubitron II File Belt, 33445, 60+ Grit, 1/2 in x 18 in, Pack of 10 File Belts, Resin Bonded, Spot Weld Removal

The 3M Cubitron II File Belt, model 33445, is a high-quality sanding belt designed for industrial use. Measuring 1/2 inch by 18 inches, this belt is made of durable, resin-bonded material, which ensures a longer lifespan. One of its key strengths is its efficiency - it cuts 30% faster and lasts twice as long as other premium abrasives, making it a reliable choice for those who need to clean, strip, deburr, or remove spot welds quickly and effectively.

Top 10 Best Sanding Belts 2025 in the United States

Winner

10.0 score

POWERTEC 4 x 24 Inch Sanding Belts, 30PK, 10 Each of 60 80 120 Grits, Aluminum Oxide Belt Sander Sanding Belt Assortment, Sandpaper for Oscillating Belt and Spindle Sander (110091)

POWERTEC 4 x 24 Inch Sanding Belts, 30PK, 10 Each of 60 80 120 Grits, Aluminum Oxide Belt Sander Sanding Belt Assortment, Sandpaper for Oscillating Belt and Spindle Sander (110091)

Chosen by 1382 this week

3M Cubitron II File Belt, 33445, 60+ Grit, 1/2 in x 18 in, Pack of 10 File Belts, Resin Bonded, Spot Weld Removal

3M Cubitron II File Belt, 33445, 60+ Grit, 1/2 in x 18 in, Pack of 10 File Belts, Resin Bonded, Spot Weld Removal

3M Cubitron II File Belt, 33446, 80+ Grit, 1/2 in x 18 in, File Belts, Resin Bonded, Spot Weld Removal, Pack of 10

3M Cubitron II File Belt, 33446, 80+ Grit, 1/2 in x 18 in, File Belts, Resin Bonded, Spot Weld Removal, Pack of 10

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.