10 Best Ryobi Impact Wrenches 2025 in the United States

Winner

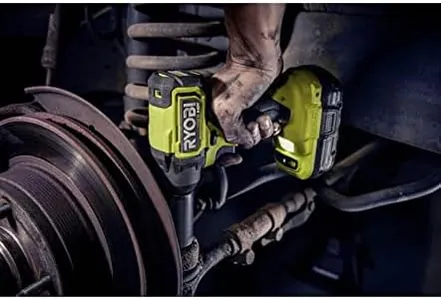

Ryobi PCL265 18V ONE+ Cordless 1/2 in. Impact Wrench (Tool ONLY- Battery and Charger NOT Included)

The Ryobi PCL265 18V ONE+ Cordless Impact Wrench is a solid choice for DIY enthusiasts and light to moderate users looking for a reliable tool without the hassle of cords. With a commendable fastening torque of 375 ft./lbs. and a speed of up to 2,700 RPM, it can handle a range of tasks, from automotive work to general home repairs. Its impressive 3,100 impacts per minute make it efficient for loosening tight bolts and fasteners. The added convenience of an onboard LED worklight enhances visibility in dimly lit areas, which many users appreciate.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!RYOBI - ONE+ HP 18V Brushless Cordless 4-Mode 1/2 in. High Torque Impact Wrench (Tool Only) - PBLIW01B

The RYOBI ONE+ HP 18V Brushless Cordless Impact Wrench is a robust tool ideal for those needing high torque and versatility in automotive and jobsite applications. With impressive breakaway torque of up to 1,170 ft-lbs., it packs a powerful punch for loosening stubborn bolts. The three-speed settings and Auto Mode provide flexibility, allowing users to tackle various tasks with ease. Plus, the tri-beam LED worklights enhance visibility, making it easier to work in dimly lit areas.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

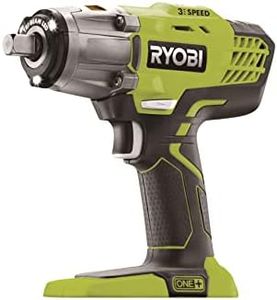

A summary of real customer reviews to highlight what shoppers are saying!Ryobii RYOBI P261K1 ONE+ 18V Cordless 3-Speed 1/2 in. Impact Wrench with 4.0 Ah Battery and Charger

The Ryobi P261K1 ONE+ 18V Cordless 3-Speed 1/2 in. Impact Wrench is a versatile tool that stands out for its high torque and flexibility. With 300 foot-pounds of torque, it’s powerful enough for most DIY and automotive tasks. The 3-speed settings allow for better control depending on the task, which can be quite handy.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 10 Best Ryobi Impact Wrenches 2025 in the United States

Winner

10.0 score

Ryobi PCL265 18V ONE+ Cordless 1/2 in. Impact Wrench (Tool ONLY- Battery and Charger NOT Included)

Ryobi PCL265 18V ONE+ Cordless 1/2 in. Impact Wrench (Tool ONLY- Battery and Charger NOT Included)

Chosen by 1164 this week

RYOBI - ONE+ HP 18V Brushless Cordless 4-Mode 1/2 in. High Torque Impact Wrench (Tool Only) - PBLIW01B

RYOBI - ONE+ HP 18V Brushless Cordless 4-Mode 1/2 in. High Torque Impact Wrench (Tool Only) - PBLIW01B

Ryobii RYOBI P261K1 ONE+ 18V Cordless 3-Speed 1/2 in. Impact Wrench with 4.0 Ah Battery and Charger

Ryobii RYOBI P261K1 ONE+ 18V Cordless 3-Speed 1/2 in. Impact Wrench with 4.0 Ah Battery and Charger

RYOBI 18V ONE+ HP Brushless Cordless Compact 3/8 -inch Impact Wrench (Tool Only)

RYOBI 18V ONE+ HP Brushless Cordless Compact 3/8 -inch Impact Wrench (Tool Only)

18V ONE+ HP COMPACT BRUSHLESS 4-MODE 1/2" IMPACT WRENCH

18V ONE+ HP COMPACT BRUSHLESS 4-MODE 1/2" IMPACT WRENCH

RYOBI R18IW3-0 18V ONE+ Cordless 3-Speed Impact Wrench (Body Only)

RYOBI R18IW3-0 18V ONE+ Cordless 3-Speed Impact Wrench (Body Only)

Ryobi ONE 18V Cordless 3/8 in. 3-Speed Impact Wrench and 3/8 in. 4-Position Ratchet Kit (Tools Only)

Ryobi ONE 18V Cordless 3/8 in. 3-Speed Impact Wrench and 3/8 in. 4-Position Ratchet Kit (Tools Only)

Ryobi P263K 18V Cordless 3/8 in. Impact Wrench Kit with 1.5 Ah Battery and Charger

Ryobi P263K 18V Cordless 3/8 in. Impact Wrench Kit with 1.5 Ah Battery and Charger

RYOBI R18IW7-0 18V ONE+ Cordless Brushless 3-Speed Impact Wrench (Body Only)

RYOBI R18IW7-0 18V ONE+ Cordless Brushless 3-Speed Impact Wrench (Body Only)

7.8 score

RYOBI - Duo ONE+ 18 V: Drill Driver + Impact Wrench - Supplied in Carry Bag with 2 Batteries 2.0 Ah + 1 Quick Charger - R18DDID-220S

RYOBI - Duo ONE+ 18 V: Drill Driver + Impact Wrench - Supplied in Carry Bag with 2 Batteries 2.0 Ah + 1 Quick Charger - R18DDID-220S

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.