10 Best Milwaukee Impact Driver 2025 in the United States

Winner

Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless 1/4'' Hex Impact Driver (Bare Tool), Red

The Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless Impact Driver stands out in several key areas, making it a solid choice for users needing a high-performance tool. One of its most notable strengths is its impressive torque of 2000 in-lbs, which allows it to handle tough tasks with ease. With a maximum rotational speed of 3900 RPM, this driver is also one of the fastest on the market, enabling users to complete tasks quickly.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

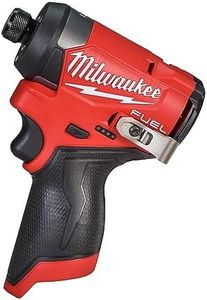

A summary of real customer reviews to highlight what shoppers are saying!Milwaukee 3453-20 12V Fuel 1/4" Cordless Hex Impact Driver (Bare Tool)

The Milwaukee 3453-20 12V Fuel 1/4" Cordless Hex Impact Driver is a compact, powerful tool designed for ease of use and portability. With a brushless motor delivering up to 1,500 in-lbs of torque, this impact driver provides strong performance for various tasks. The lightweight design at 2 lbs makes it easy to carry and reduces fatigue during prolonged use, making it suitable for daily tasks and professional use alike.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Milwaukee ELEC TOOL 2760-20 M18 Fuel Hex Hydraulic Driver, 1/4"

The Milwaukee ELEC TOOL 2760-20 M18 Fuel Hex Hydraulic Driver is a robust and efficient tool designed to meet the needs of users looking for high performance in their impact drivers. One of its standout features is the fluid-drive hydraulic powertrain, which significantly reduces metal-on-metal contact, resulting in quieter operation and smoother performance compared to standard impact drivers. This makes it particularly suitable for those who value a quieter working environment and prefer tools with enhanced durability.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 10 Best Milwaukee Impact Driver 2025 in the United States

Winner

9.9 score

Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless 1/4'' Hex Impact Driver (Bare Tool), Red

Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless 1/4'' Hex Impact Driver (Bare Tool), Red

Chosen by 1405 this week

Milwaukee 3453-20 12V Fuel 1/4" Cordless Hex Impact Driver (Bare Tool)

Milwaukee 3453-20 12V Fuel 1/4" Cordless Hex Impact Driver (Bare Tool)

Milwaukee ELEC TOOL 2760-20 M18 Fuel Hex Hydraulic Driver, 1/4"

Milwaukee ELEC TOOL 2760-20 M18 Fuel Hex Hydraulic Driver, 1/4"

M12 Drill/Impact Combo Kit - Milwaukee 2494-22

M12 Drill/Impact Combo Kit - Milwaukee 2494-22

Milwaukee 2656-20 M18 18V 1/4 Inch Lithium Ion Hex Impact Driver with 1,500 Inch Pounds of Torque and LED Lighting Array (Battery Not Included, Power Tool Only)

Milwaukee 2656-20 M18 18V 1/4 Inch Lithium Ion Hex Impact Driver with 1,500 Inch Pounds of Torque and LED Lighting Array (Battery Not Included, Power Tool Only)

Milwaukee 2562-22 M12 FUEL™ Stubby 3/8" Impact Wrench Kit

Milwaukee 2562-22 M12 FUEL™ Stubby 3/8" Impact Wrench Kit

Milwaukee 2697-22CT M18 18-Volt Lithium-Ion Cordless Hammer Drill/Impact Driver Combo Kit

Milwaukee 2697-22CT M18 18-Volt Lithium-Ion Cordless Hammer Drill/Impact Driver Combo Kit

Milwaukee 2850-21P M18 Brushless Lithium-Ion Compact 1/4 in. Cordless Hex Impact Driver Kit (2 Ah)

Milwaukee 2850-21P M18 Brushless Lithium-Ion Compact 1/4 in. Cordless Hex Impact Driver Kit (2 Ah)

M12 Fuel 12V 1/4" Lithium-ion Cordless Impact Driver Kit - with 2 Batteries, Charger, and Tool Case

M12 Fuel 12V 1/4" Lithium-ion Cordless Impact Driver Kit - with 2 Batteries, Charger, and Tool Case

7.9 score

Milwaukee 3650-20 M18 18V Lithium-Ion Brushless Cordless 1/4 in. Compact Impact Driver (Tool Only), Red

Milwaukee 3650-20 M18 18V Lithium-Ion Brushless Cordless 1/4 in. Compact Impact Driver (Tool Only), Red

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.