10 Best Masking Tapes 2025 in the United States

Winner

FROGTAPE Multi-Surface Painter's Tape with PAINTBLOCK, Medium Adhesion, 1.88 Inches x 60 Yards, Green, 3 Rolls (240661)

The FrogTape Multi-Surface Painters Tape is a premium grade masking tape designed for use in various painting applications. It has a medium adhesive strength, making it suitable for most common paint jobs without damaging surfaces. With a width of 2 inches, it covers a decent area, reducing the need for multiple strips. The material used is crepe paper, which is flexible and conforms well to different surfaces.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

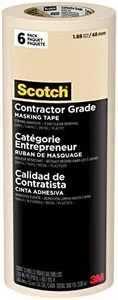

A summary of real customer reviews to highlight what shoppers are saying!Scotch Contractor Grade Masking Tape, Tan, Tape for General Use, Multi-Surface Adhesive Tape, 0.94 Inches x 60.1 Yards, 9 Rolls

The Scotch Contractor Grade Masking Tape is designed for both indoor and outdoor use, with strong adhesion suitable for surfaces like vinyl, carpet, metal, and plastic. Its width of 0.94 inches makes it versatile for various applications, while the total length of 540 yards (9 rolls each containing 60.1 yards) ensures a generous supply for extensive projects. Made from crepe paper, the tape promises durability and flexibility in usage.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 10 Best Masking Tapes 2025 in the United States

Winner

9.9 score

FROGTAPE Multi-Surface Painter's Tape with PAINTBLOCK, Medium Adhesion, 1.88 Inches x 60 Yards, Green, 3 Rolls (240661)

FROGTAPE Multi-Surface Painter's Tape with PAINTBLOCK, Medium Adhesion, 1.88 Inches x 60 Yards, Green, 3 Rolls (240661)

Chosen by 1178 this week

Scotch Contractor Grade Masking Tape, Tan, Tape for General Use, Multi-Surface Adhesive Tape, 0.94 Inches x 60.1 Yards, 9 Rolls

Scotch Contractor Grade Masking Tape, Tan, Tape for General Use, Multi-Surface Adhesive Tape, 0.94 Inches x 60.1 Yards, 9 Rolls

FrogTape ProGrade Orange Painters Tape, 1.5 Inch Wide (1.41 In. x 60 Yds), High Adhesion, Paint Tape for Indoor & Outdoor Applications, Orange, 4 Rolls (242808)

FrogTape ProGrade Orange Painters Tape, 1.5 Inch Wide (1.41 In. x 60 Yds), High Adhesion, Paint Tape for Indoor & Outdoor Applications, Orange, 4 Rolls (242808)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.