7 Best Jet Planers 2025 in the United States

Winner

WEN Cordless Planer, Brushless with 3-1/4-Inch Blade, 20V Max 4.0 Ah Lithium-Ion Battery and Charger (20653)

The WEN Cordless Planer (20653) offers a blend of power and convenience with its brushless motor and cordless design. The brushless motor ensures better performance and a longer lifespan with less maintenance, which is advantageous for frequent users. The dual 3-1/4-inch blades deliver an impressive 26,000 cuts per minute, making it efficient for smoothing and leveling wood surfaces. With adjustable cutting depths up to 1/8 inches in 1/128-inch increments, it allows for precise control over your work. The included 4.0 amp-hour lithium-ion battery provides consistent power and is compatible with other WEN 20V Max tools, which adds versatility for users who own other products in the series.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

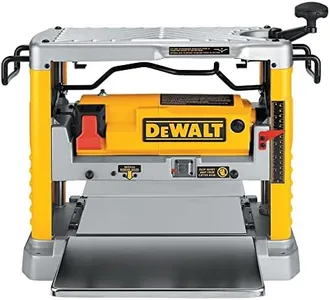

A summary of real customer reviews to highlight what shoppers are saying!DEWALT Benchtop Planer, 15-Amp, 12-1/2-Inch, 3-Knife Cutter, 20,000 RPM, Corded (DW734)

The DEWALT Benchtop Planer (DW734) is a powerful and reliable tool, ideal for woodworking enthusiasts and professionals who need precise and smooth finishes. Its 15-amp motor and 20,000 RPM provide ample power for handling large and deep cuts, even in hardwoods. The three-knife cutter head with a 10,000 RPM speed delivers 96 cuts per inch, producing one of the finest finishes among portable planers. The knives are disposable and reversible, extending their life by 30% and making replacements quick and easy.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Top 7 Best Jet Planers 2025 in the United States

Winner

9.8 score

WEN Cordless Planer, Brushless with 3-1/4-Inch Blade, 20V Max 4.0 Ah Lithium-Ion Battery and Charger (20653)

WEN Cordless Planer, Brushless with 3-1/4-Inch Blade, 20V Max 4.0 Ah Lithium-Ion Battery and Charger (20653)

Chosen by 1140 this week

DEWALT Benchtop Planer, 15-Amp, 12-1/2-Inch, 3-Knife Cutter, 20,000 RPM, Corded (DW734)

DEWALT Benchtop Planer, 15-Amp, 12-1/2-Inch, 3-Knife Cutter, 20,000 RPM, Corded (DW734)

JET 13-Inch Benchtop Planer, Helical Style, 18/26 FPM, 120V 1Ph (Model JWP-13BT)

JET 13-Inch Benchtop Planer, Helical Style, 18/26 FPM, 120V 1Ph (Model JWP-13BT)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.