10 Best Home Cnc Machine 2025 in the United States

Winner

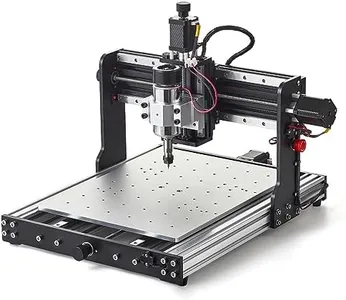

FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor, 400W Spindle 3 Axis Engraving Milling Machine for Wood Acrylic Aluminum Carving Cutting

The FoxAlien Masuter 3S CNC Router Machine stands out in the home CNC machine category, particularly for those interested in wood, acrylic, and even soft metal projects. With a solid build quality thanks to its sturdy extrusions and dual linear rails, it offers stability and high accuracy during use, achieving a precision of 0.05mm. The 400W spindle power ensures that users can engrave and cut materials effectively, enhancing its versatility for various projects.

Most important from

41 reviews

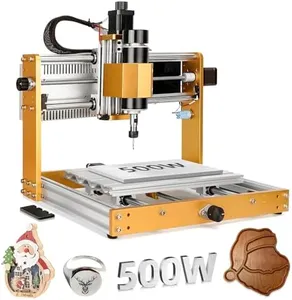

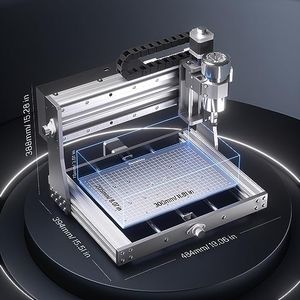

Genmitsu 3020-PRO MAX V2 CNC Router Machine, Upgraded 3 Axis Engraver for Metal, Wood, Acrylic, PCB MDF, New Structure & Offline Controller & 6pcs Limit Switches, Working Area 11.8 x 8.1 x 3.1 inch

The Genmitsu 3020-PRO MAX V2 CNC Router is a solid choice for home CNC enthusiasts. It features a work area of 11.8"x8.1"x3.1", which is adequate for various small to medium-sized projects. The 300W spindle allows for effective cutting and engraving on materials such as metal, wood, acrylic, PCB, and MDF. The machine's precision and accuracy are bolstered by its upgraded dual steel X-axis guide rail and integrated molded Z-axis C-mount, which offer improved stability and performance over previous models.

Most important from

1849 reviews

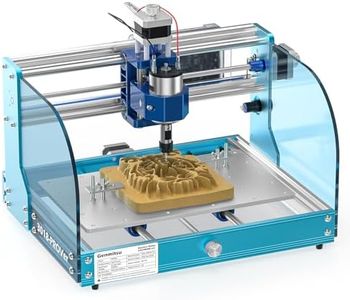

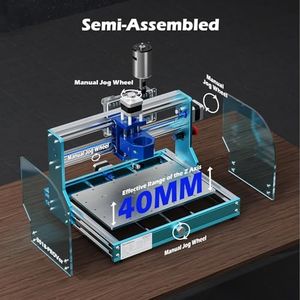

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

The FoxAlien Masuter Pro CNC Router Machine is a solid choice for home and hobbyist CNC machining. Its all-aluminum build enhances durability and precision, while the linear rail Z-axis upgrade significantly improves stability and accuracy. This machine offers a spacious working area of 15.75” x 15.75” x 2.36”, which is suitable for most woodworking and carving projects, and it can be extended further with an optional Y-axis extension kit.

Most important from

438 reviews

Top 10 Best Home Cnc Machine 2025 in the United States

Winner

9.9 score

FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor, 400W Spindle 3 Axis Engraving Milling Machine for Wood Acrylic Aluminum Carving Cutting

FoxAlien Masuter 3S CNC Router Machine with NEMA 23 Closed-Loop Stepper Motor, 400W Spindle 3 Axis Engraving Milling Machine for Wood Acrylic Aluminum Carving Cutting

Chosen by 1332 this week

Genmitsu 3020-PRO MAX V2 CNC Router Machine, Upgraded 3 Axis Engraver for Metal, Wood, Acrylic, PCB MDF, New Structure & Offline Controller & 6pcs Limit Switches, Working Area 11.8 x 8.1 x 3.1 inch

Genmitsu 3020-PRO MAX V2 CNC Router Machine, Upgraded 3 Axis Engraver for Metal, Wood, Acrylic, PCB MDF, New Structure & Offline Controller & 6pcs Limit Switches, Working Area 11.8 x 8.1 x 3.1 inch

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

Genmitsu CNC Router Machine PROVerXL 4030 for Wood Metal Acrylic MDF Carving Arts Crafts DIY Design, 3 Axis Milling Cutting Engraving Machine, Working Area 400 x 300 x 110mm (15.7''x11.8''x4.3'')

Genmitsu CNC Router Machine PROVerXL 4030 for Wood Metal Acrylic MDF Carving Arts Crafts DIY Design, 3 Axis Milling Cutting Engraving Machine, Working Area 400 x 300 x 110mm (15.7''x11.8''x4.3'')

FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle 3-Axis Engraving Milling Machine for Wood Aluminum Cutting Upgradable to Linear Rails

FoxAlien CNC Router Machine XE-PRO with Ball Screws, 400W Spindle 3-Axis Engraving Milling Machine for Wood Aluminum Cutting Upgradable to Linear Rails

Genmitsu CNC Router Machine PROVerXL 4030 V2, Fast Speed for Wood Metal Acrylic PCB MDF, Upgrade 3 Axis Engraving Machine with Closed-Loop Motor and Ball Screw, Working Area 400 x 300 x 110mm

Genmitsu CNC Router Machine PROVerXL 4030 V2, Fast Speed for Wood Metal Acrylic PCB MDF, Upgrade 3 Axis Engraving Machine with Closed-Loop Motor and Ball Screw, Working Area 400 x 300 x 110mm

Genmitsu CNC Router Machine 4040-PRO for Metal Acrylic Cutting Milling, GRBL Control, Lead Screw Driven, 3 Axis Engraving, Working Area 15.7” x 15.7” x 3.1”

Genmitsu CNC Router Machine 4040-PRO for Metal Acrylic Cutting Milling, GRBL Control, Lead Screw Driven, 3 Axis Engraving, Working Area 15.7” x 15.7” x 3.1”

VEVOR CNC Router Machine, 300W, 3 Axis GRBL Control Wood Engraving Carving Milling Machine Kit, 400 x 400 x 75 mm / 15.7 x 15.7 x 2.95 in Working Area 12000 RPM for Wood Acrylic MDF PVC Plastic Foam

VEVOR CNC Router Machine, 300W, 3 Axis GRBL Control Wood Engraving Carving Milling Machine Kit, 400 x 400 x 75 mm / 15.7 x 15.7 x 2.95 in Working Area 12000 RPM for Wood Acrylic MDF PVC Plastic Foam

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

![RIEDHOFF X-Axis Power Milling Machine, [450 LB Torque ] Power Feed Table Mill,110V, 0-200PRM Adjustable Rotate Speed for Bridgeport and Similar Knee Type Milling Machines,White](https://images-proxy.bestreviews.guide/98_BqUqyRyW66e-SErSzrbPrJ8c=/0x300/https://m.media-amazon.com/images/I/41UHXMx+9XL._AC_CX679_.jpg)

![Garvee Z-Axis Power Feed for Power Milling Machine, [450 LB Torque]110V, 0-200PRM Adjustable Rotate Speed for Bridgeport and Similar Knee Type Milling Machines](https://images-proxy.bestreviews.guide/_GdzehAT4hZ1w-_DZdegJO-rlDc=/0x300/https://m.media-amazon.com/images/I/41N1fxmEFDL._AC_CX679_.jpg)