10 Best Epoxy For Aluminum 2025 in the United States

Winner

24 Pack Metal Glue,1.76oz 2 Part 5 Min Epoxy Glue, High Strength High Temperature Resistant Adhesive Body Filler, Marine Sealant,Liquid Steel Cold Weld Plastic,Aluminum,Wood,Marine epoxy Putty Repair

This 24 Pack Metal Glue offers a versatile solution for various repair needs, particularly for aluminum and other materials. With a quick 5-minute setting time and full cure in 24 hours, it’s ideal for those who need efficient, strong adhesion. The epoxy displays impressive strength, reaching up to 4680 psi, making it suitable for heavy-duty applications like automotive and marine repairs. Its temperature resistance is noteworthy, functioning well between -65°C and 287°C, which allows it to hold up in extreme conditions.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!TotalBoat-434282 TotalFair Marine Epoxy Fairing Compound for Fiberglass, Wood, Aluminum and Steel (2 Pint Kit)

The TotalBoat-434282 TotalFair Marine Epoxy Fairing Compound stands out as a solid choice for anyone looking to repair or fair surfaces on boats, canoes, and other watercraft, including aluminum. One of its key strengths is its high strength and lightweight nature, making it effective for filling dents and holes while ensuring the repair won't weigh down the structure. The easy 1-to-1 mixing ratio is user-friendly, allowing even beginners to achieve an excellent blend without fuss. It cures relatively quickly, needing just about 4 hours before it can be sanded, which is a significant advantage for those eager to finish their projects swiftly. Plus, its waterproof nature is a must for marine applications, ensuring that repairs hold up well even when submerged or exposed to water.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!TotalBoat-439901 TotalProtect Epoxy Barrier Coat System (White, Gallon), 1 Gallon (Pack of 1)

The TotalBoat-439901 TotalProtect Epoxy Barrier Coat System is a solid option for those looking to protect aluminum surfaces, especially in marine environments. It stands out with its high-build formula that creates a flexible and durable barrier, making it effective for both above and below water applications. The fast-drying feature is a significant advantage, allowing users to proceed without long wait times. Plus, it’s easy to apply using a roller or spray, which is great for those not keen on complicated application methods. The product also offers good coverage, approximately 225 square feet per gallon at the recommended thickness, which makes it economical for larger projects.

Top 10 Best Epoxy For Aluminum 2025 in the United States

Winner

9.9 score

24 Pack Metal Glue,1.76oz 2 Part 5 Min Epoxy Glue, High Strength High Temperature Resistant Adhesive Body Filler, Marine Sealant,Liquid Steel Cold Weld Plastic,Aluminum,Wood,Marine epoxy Putty Repair

24 Pack Metal Glue,1.76oz 2 Part 5 Min Epoxy Glue, High Strength High Temperature Resistant Adhesive Body Filler, Marine Sealant,Liquid Steel Cold Weld Plastic,Aluminum,Wood,Marine epoxy Putty Repair

Chosen by 1374 this week

TotalBoat-439901 TotalProtect Epoxy Barrier Coat System (White, Gallon), 1 Gallon (Pack of 1)

TotalBoat-439901 TotalProtect Epoxy Barrier Coat System (White, Gallon), 1 Gallon (Pack of 1)

Cerca de Metal Repair Glue,Strongest Glue for Metal to Metal,Suitable for Metal,Stone, Plastic, Aluminum, Steel, All Purpose Repair Glue,Liquid Metal Filler,epoxy,Weld,Heavy Duty, Waterproof,1.6oz

Cerca de Metal Repair Glue,Strongest Glue for Metal to Metal,Suitable for Metal,Stone, Plastic, Aluminum, Steel, All Purpose Repair Glue,Liquid Metal Filler,epoxy,Weld,Heavy Duty, Waterproof,1.6oz

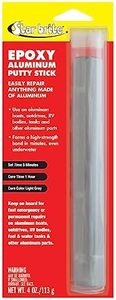

STAR BRITE Epoxy Aluminum Putty Stick - Make Fast, Permanent Repairs - Even Underwater - Aluminum 4 OZ. (087004)

STAR BRITE Epoxy Aluminum Putty Stick - Make Fast, Permanent Repairs - Even Underwater - Aluminum 4 OZ. (087004)

Devcon 10610 Aluminum Putty (F), 1 lb. Can

Devcon 10610 Aluminum Putty (F), 1 lb. Can

Hy-Poxy H-455 Alumfast 6.5 oz Rapid Cure Aluminum Putty Repair Kit

Hy-Poxy H-455 Alumfast 6.5 oz Rapid Cure Aluminum Putty Repair Kit

7.7 score

METALSET A4 Aluminum Filled EPOXY Adhesive 11 Ounce

METALSET A4 Aluminum Filled EPOXY Adhesive 11 Ounce

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.