10 Best Cordless Impact Wrenches 2025 in the United States

Winner

Milwaukee 2967-20 M18 FUEL™ 1/2" High Torque Impact Wrench w/ Friction Ring (Tool Only)

The Milwaukee 2967-20 M18 FUEL™ ½" High Torque Impact Wrench stands out in the cordless impact wrench category, particularly for those seeking high torque and versatile performance. It boasts an impressive brushless motor that can deliver up to 1,100 ft-lbs of fastening torque and an even more remarkable 1,600 ft-lbs of nut-busting torque. This power makes it ideal for heavy-duty applications like automotive work or construction projects where tough fasteners are common.

Most important from

956 reviews

DEWALT 20V MAX Cordless Impact Wrench, 1/2 in., Bare Tool Only (DCF900B)

The DEWALT 20V MAX Cordless Impact Wrench (DCF900B) is a robust tool designed to handle a wide range of fastening tasks, boasting impressive torque capabilities with 1030 ft-lbs of max fastening torque and 1400 ft-lbs of max breakaway torque. This makes it powerful enough for challenging jobs. The tool's 4-mode speed settings and variable speed trigger offer excellent control, making it versatile for different applications.

Most important from

1679 reviews

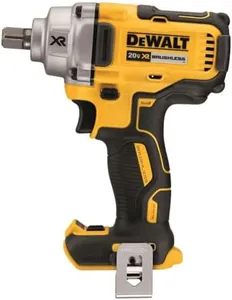

DEWALT 20V MAX Cordless Impact Wrench, 1/2" Hog Ring, High Torque, Brushless, Bare Tool Only (DCF961B)

The DEWALT 20V MAX Cordless Impact Wrench is a highly capable tool designed for heavy-duty fastening tasks. With an impressive max torque of 1200 ft-lbs and breakaway torque of 1750 ft-lbs, it stands out as one of the most powerful options in its category, making it suitable for both professionals and serious DIY enthusiasts. The inclusion of three speed settings and a precision wrench mode adds versatility, enabling users to prevent overtightening and manage various fastening tasks effectively.

Most important from

442 reviews

Top 10 Best Cordless Impact Wrenches 2025 in the United States

Winner

9.9 score

Milwaukee 2967-20 M18 FUEL™ 1/2" High Torque Impact Wrench w/ Friction Ring (Tool Only)

Milwaukee 2967-20 M18 FUEL™ 1/2" High Torque Impact Wrench w/ Friction Ring (Tool Only)

Chosen by 1295 this week

DEWALT 20V MAX Cordless Impact Wrench, 1/2 in., Bare Tool Only (DCF900B)

DEWALT 20V MAX Cordless Impact Wrench, 1/2 in., Bare Tool Only (DCF900B)

DEWALT 20V MAX Cordless Impact Wrench, 1/2" Hog Ring, High Torque, Brushless, Bare Tool Only (DCF961B)

DEWALT 20V MAX Cordless Impact Wrench, 1/2" Hog Ring, High Torque, Brushless, Bare Tool Only (DCF961B)

Robustrue Cordless Impact Wrench, 406Ft-lbs (550N.m) Brushless 1/2 inch, 2800RPM High Torque Impact Gun, 2x 4.0Ah Battery, Charger, 4 Sockets, Electric Impact Wrench for Car Home

Robustrue Cordless Impact Wrench, 406Ft-lbs (550N.m) Brushless 1/2 inch, 2800RPM High Torque Impact Gun, 2x 4.0Ah Battery, Charger, 4 Sockets, Electric Impact Wrench for Car Home

Milwaukee 2962-20 M18 18V Fuel 1/2" Mid-torque Impact Wrench with Friction Ring

Milwaukee 2962-20 M18 18V Fuel 1/2" Mid-torque Impact Wrench with Friction Ring

DEWALT 20V MAX Impact Wrench, Cordless 2-Tool Combo Kit, 1/2-Inch Mid-Range and 3/8-inch Compact with 5ah Battery and Charger (DCK205P1)

DEWALT 20V MAX Impact Wrench, Cordless 2-Tool Combo Kit, 1/2-Inch Mid-Range and 3/8-inch Compact with 5ah Battery and Charger (DCK205P1)

Makita XWT08Z 18V LXT® Lithium-Ion Brushless Cordless High-Torque 1/2" Sq. Drive Impact Wrench, Tool Only

Makita XWT08Z 18V LXT® Lithium-Ion Brushless Cordless High-Torque 1/2" Sq. Drive Impact Wrench, Tool Only

DEWALT DCF913B 20V MAX* 3/8 in. Cordless Impact Wrench with Hog Ring Anvil (Tool Only)

DEWALT DCF913B 20V MAX* 3/8 in. Cordless Impact Wrench with Hog Ring Anvil (Tool Only)

Milwaukee 2855-20 18V Brushless Cordless 1/2" Impact Wrench with Friction Ring

Milwaukee 2855-20 18V Brushless Cordless 1/2" Impact Wrench with Friction Ring

7.8 score

MILWAUKEE'S Mid-Torque Impact Wrench,3/8",Cordless

MILWAUKEE'S Mid-Torque Impact Wrench,3/8",Cordless

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.