10 Best Cordless Impact Drivers 2025 in the United States

Winner

DEWALT 20V MAX Cordless Drill and Impact Driver, Power Tool Combo Kit with 2 Batteries and Charger (DCK240C2)

The DEWALT 20V MAX Cordless Drill and Impact Driver Combo Kit (DCK240C2) is a robust choice for both DIY enthusiasts and professionals looking for reliable cordless power tools. The kit includes a 20V drill and an impact driver, both delivering substantial power with a high-performance motor and a 20V battery. The two-speed transmission offers flexibility, with speeds up to 1500 RPM, suitable for a variety of applications.

Most important from

53379 reviews

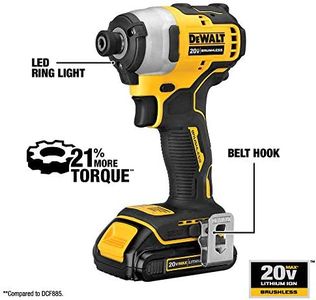

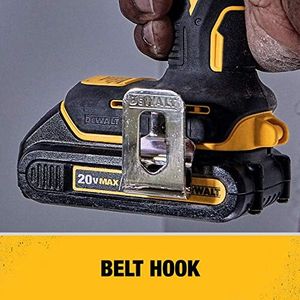

DEWALT 20V MAX XR Impact Driver, Brushless, 1/4", 3-Speed, Bare Tool Only (DCF845B)

The DEWALT 20V MAX XR Impact Driver, Brushless (DCF845B), is a high-performance tool that caters well to professional and heavy-duty user needs. It operates on a powerful 20V battery, ensuring strong performance and reliability. One of its standout features is the brushless motor, delivering an impressive 1825 in-lbs of torque, making it suitable for driving large diameter screws and other tough fastening applications.

Most important from

11678 reviews

DEWALT 20V MAX Cordless Drill, Impact Driver, 2-Tool Power Tool Combo Kit, Brushless Power Tool Set with 2 Batteries and Charger Included (DCK277D2)

The DEWALT 20V MAX Cordless Drill and Impact Driver Combo Kit is a solid choice for anyone needing reliable cordless impact drivers. This kit features a compact and lightweight design, making it easy to handle and ideal for tight spaces. The ergonomic comfort grip ensures good balance and control, which is helpful during extended use.

Most important from

2387 reviews

Top 10 Best Cordless Impact Drivers 2025 in the United States

Winner

9.7 score

DEWALT 20V MAX Cordless Drill and Impact Driver, Power Tool Combo Kit with 2 Batteries and Charger (DCK240C2)

DEWALT 20V MAX Cordless Drill and Impact Driver, Power Tool Combo Kit with 2 Batteries and Charger (DCK240C2)

Chosen by 1400 this week

DEWALT 20V MAX XR Impact Driver, Brushless, 1/4", 3-Speed, Bare Tool Only (DCF845B)

DEWALT 20V MAX XR Impact Driver, Brushless, 1/4", 3-Speed, Bare Tool Only (DCF845B)

DEWALT 20V MAX Cordless Drill, Impact Driver, 2-Tool Power Tool Combo Kit, Brushless Power Tool Set with 2 Batteries and Charger Included (DCK277D2)

DEWALT 20V MAX Cordless Drill, Impact Driver, 2-Tool Power Tool Combo Kit, Brushless Power Tool Set with 2 Batteries and Charger Included (DCK277D2)

Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless 1/4'' Hex Impact Driver (Bare Tool), Red

Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless 1/4'' Hex Impact Driver (Bare Tool), Red

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.