10 Best Air Compressor Hoses 2025 in the United States

Winner

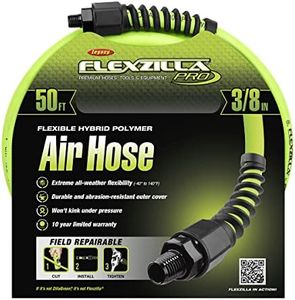

Flexzilla Air Hose, 3/8 in. x 50 ft., 1/4 in. MNPT Fittings, Heavy Duty, Lightweight, Hybrid, ZillaGreen - HFZ3850YW2

The Flexzilla Air Hose is a versatile option for various applications, including professional jobsites, automotive shops, and home garages. Made from a flexible hybrid polymer, it offers excellent flexibility in all weather conditions, with a temperature range from -40°F to 140°F. This makes it ideal for use in extreme climates. The hose is 50 feet long and has a diameter of 3/8 inches, with 1/4 inch MNPT fittings.

Most important from

11226 reviews

Goodyear Air Hose Reel Retractable 3/8" Inch x 50' Foot SBR Rubber Hose Max 300PSI Heavy Duty Industrial Steel Single Arm Construction

The Goodyear Air Hose Reel is a solid choice for those needing a reliable air compressor hose. It features a 50-foot long, 3/8-inch diameter hose made from premium SBR rubber, known for its durability and stability. This hose is resistant to water, oil, heat, weather, and abrasion, making it suitable for various environments. Additionally, it can operate in extreme temperatures, from -40°F to 226°F. This flexibility ensures it can handle both indoor and outdoor tasks, whether for DIY projects or industrial uses.

Most important from

1288 reviews

Top 10 Best Air Compressor Hoses 2025 in the United States

Winner

9.9 score

Flexzilla Air Hose, 3/8 in. x 50 ft., 1/4 in. MNPT Fittings, Heavy Duty, Lightweight, Hybrid, ZillaGreen - HFZ3850YW2

Flexzilla Air Hose, 3/8 in. x 50 ft., 1/4 in. MNPT Fittings, Heavy Duty, Lightweight, Hybrid, ZillaGreen - HFZ3850YW2

Chosen by 1325 this week

Goodyear Air Hose Reel Retractable 3/8" Inch x 50' Foot SBR Rubber Hose Max 300PSI Heavy Duty Industrial Steel Single Arm Construction

Goodyear Air Hose Reel Retractable 3/8" Inch x 50' Foot SBR Rubber Hose Max 300PSI Heavy Duty Industrial Steel Single Arm Construction

Goodyear Retractable Air Hose Reel, 3/8" x 100 Feet, 300 PSI, Spring-Driven Steel, Heavy Duty Industrial, Flex Hybrid Polymer Hose, Portable and Durable

Goodyear Retractable Air Hose Reel, 3/8" x 100 Feet, 300 PSI, Spring-Driven Steel, Heavy Duty Industrial, Flex Hybrid Polymer Hose, Portable and Durable

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.